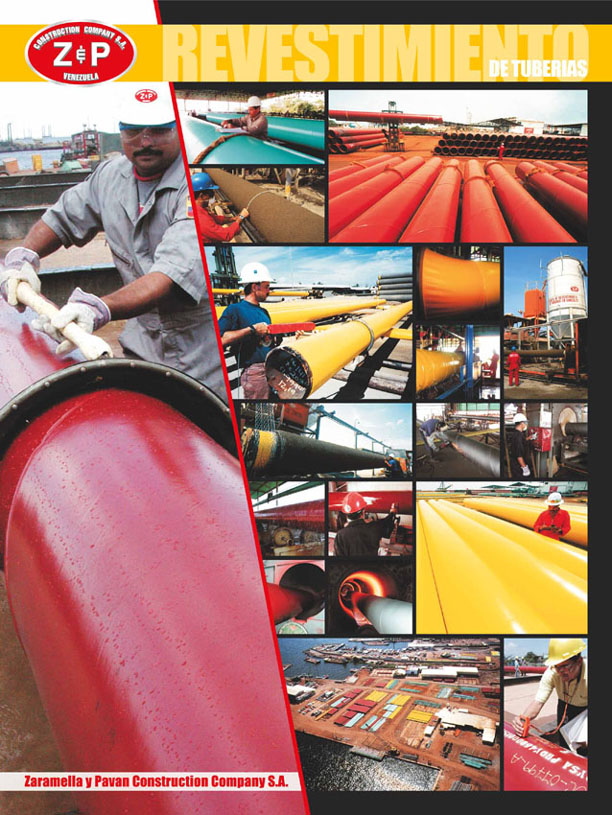

Pipe Coating (Coating of pipes with concrete)

Z & P traditionally throughout its history has offered coating services in its different forms both on-site and applied in coating plants. Since its early operations, coatings were offered with coal tar and polyethylene tapes that were replaced over time with materials and technologies that guaranteed greater performance and durability. Z & P in the 60s installed in its yard of Las Morochas, Zulia state of Venezuela, its first external pipe coating plant with high density polyethylene (P.E.A.D.); Then, Z&P installed an external pipe coating plant with concrete to give it greater mechanical protection and weight to avoid buoyancy in the construction of underwater pipelines. Finally, in the 1980s, Z&P installed an external coating plant for pipes with fusion bonded epoxy coating (F.B.E.), for low and high pipelines service temperatures

| HIGH DENSITY POLYETHYLENE | Manufacture and installation of the first portable plant | First company in Latin America to obtain ISO 9001 quality certification. |

| FUSION BONDED EPOXY | Application of the first system for service temperatures above 65C and 95C | First company to apply anti-slippage epoxy for the service of coating with concrete |

| CONCRETE | Coating of 40-inch pipes for underwater service | Technical development of heavy aggregate product for high density concrete |

English (UK)

English (UK)  Español (ES)

Español (ES)